How Engineering Data Drives Manufacturer Efficiency

Smart manufacturing often conjures images of robotic arms, IoT sensors, and AI-powered dashboards. But one of the most under-leveraged assets in this transformation journey is engineering data, especially the rich yet fragmented information embedded in CAD models, drawings, and BOMs.

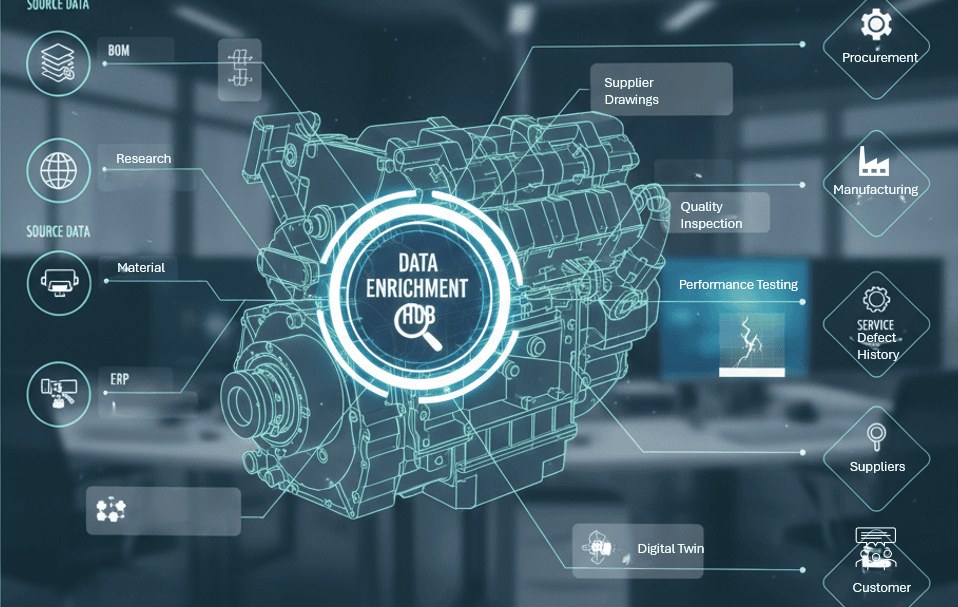

Manufacturers today sit on terabytes of design files, yet struggle to convert them into organizational-ready assets. These files are often locked in siloed folders, poorly tagged, and disconnected from downstream systems like ERP, MES, CPQ, and maintenance platforms. As a result, companies face repeated engineering effort, misalignment across departments, and missed opportunities to accelerate delivery and reduce cost.

This engineering problem of silos, fragmented data and tagging is receiving a lot of attention, with startups and CAD players looking to solve with ML/AI. Time to start taking advantage of these tools.

This blog builds on our prior post on design reuse and moves one layer deeper, exploring how to structure and connect engineering data so it becomes an operational and financial advantage.

The Hidden Cost of Unstructured Engineering Data

Engineering teams generate immense value and assets: product drawings, component models, configuration variants, and manufacturing instructions. I found that the basic SOPs for design data management frequently became diluted.

Standard naming conventions

Searchable metadata (material, performance, usage context)

Clear lineage of changes or reuse across projects

Links to production and ERP systems

If your CAD libraries are hard to search, or if each engineer creates their own naming logic, you are paying a tax across the product lifecycle. Here are common symptoms of poor data structure:

Long quoting cycles because prior designs are hard to retrieve

Rework caused by minor variations of already-solved problems

Inventory bloat due to unnecessary part variants

Slow onboarding of engineers who cannot easily navigate legacy designs

Maintenance delays from unclear service procedures or component lineage

These are not isolated engineering problems. They erode operational responsiveness, inflate working capital, and delay revenue.

Making Design Assets Discoverable and Usable

The first step in unlocking value from engineering data is to treat it as a product, not just project output. This means:

Tagging and Metadata: Standardize feature-level tags (function, fit, interface, material, tolerances) so components are searchable.

Version Control and Lineage: Track the evolution of parts and subassemblies. Know which project used what design, and what changes were made.

Searchable Repositories: Move beyond folder trees. Use visual search, attribute filters, or try AI-based similarity search to locate parts.

Bill of Information (BOI): Go beyond the BOM. Include manufacturability, quality, and service attributes in the design record.

When done well, this transforms a CAD file from static geometry into a connected, reusable, and monetizable asset. Your CAD asset now serves multiple stakeholders, both internal and external, and becomes the foundational data that can be used in multiple tools used in your organization. Here are a few ways in which engineering data enables other functions practically:

| Capability | Engineering Data Role |

| Digital Twin | Feed geometry, tolerance and fit checks into virtual simulations |

| Predictive Maintenance | Link component history to service manuals and sensor alerts |

| Production scheduling | Enable cycle time estimation via process linked parts |

| Configure-Price-Quote | Identify reusable configurations, validate constraints |

Making engineering data usable across the organization requires changes in standards, ownership, and mindset.

Design Library Stewardship: Assign owners for tagging, quality, and version control.

Process Integration: Link PLM or PDM systems with ERP, MES, and service platforms.

Training and Onboarding: Educate engineers to design with reuse and metadata in mind.

KPIs: Track reuse rate, part lineage clarity, and time-to-quote to demonstrate impact.

Engineers can take advantage of new tools/ feature sets inside CAD that are making this administrative task easier. We pay attention to $$ for financial accuracy. Accuracy and ease of design data usability has direct and indirect cost impact on the organization (rework costs, warranty costs, lost opportunity cost, onboarding & time to competency, etc.).

Call to Action: Start with your next project.

A full overhaul is not required to see impact. Start with one product family or platform:

Audit existing CAD files for redundancy and undocumented variations.

Define tagging standards for components and assemblies.

Link designs to quoting, production, or service use cases.

Demonstrate business impact via quoting time reduction, reuse rate, or inventory streamlining.

Once the value is visible, it becomes easier to scale.

Refer previous blog on Design Reusability: https://www.mtabusa.com/blogs/post/why-design-reuse-belongs-in-smart-manufacturing-playbook