How Reuse Drives Utilization in OEM Engineering

Smart manufacturing is not just about connected sensors, AI algorithms, or real-time dashboards. It is about improving how work gets done across the entire value chain, especially that which impacts customers. One often overlooked but critical pillar of smart manufacturing is engineering productivity. Specifically, I want to talk about how effectively a company reuses its own design assets to dramatically influence its ability to scale, automate, and respond to customer needs. Design reuse is a strategic lever for reducing lead times, improving quality, and accelerating quoting and production cycles. It makes a stronger case for smarter Product Lifecycle Management and financial metrics that matter to the C-Suite (Inventory Turns, Product Development Cost, Warranty Costs).

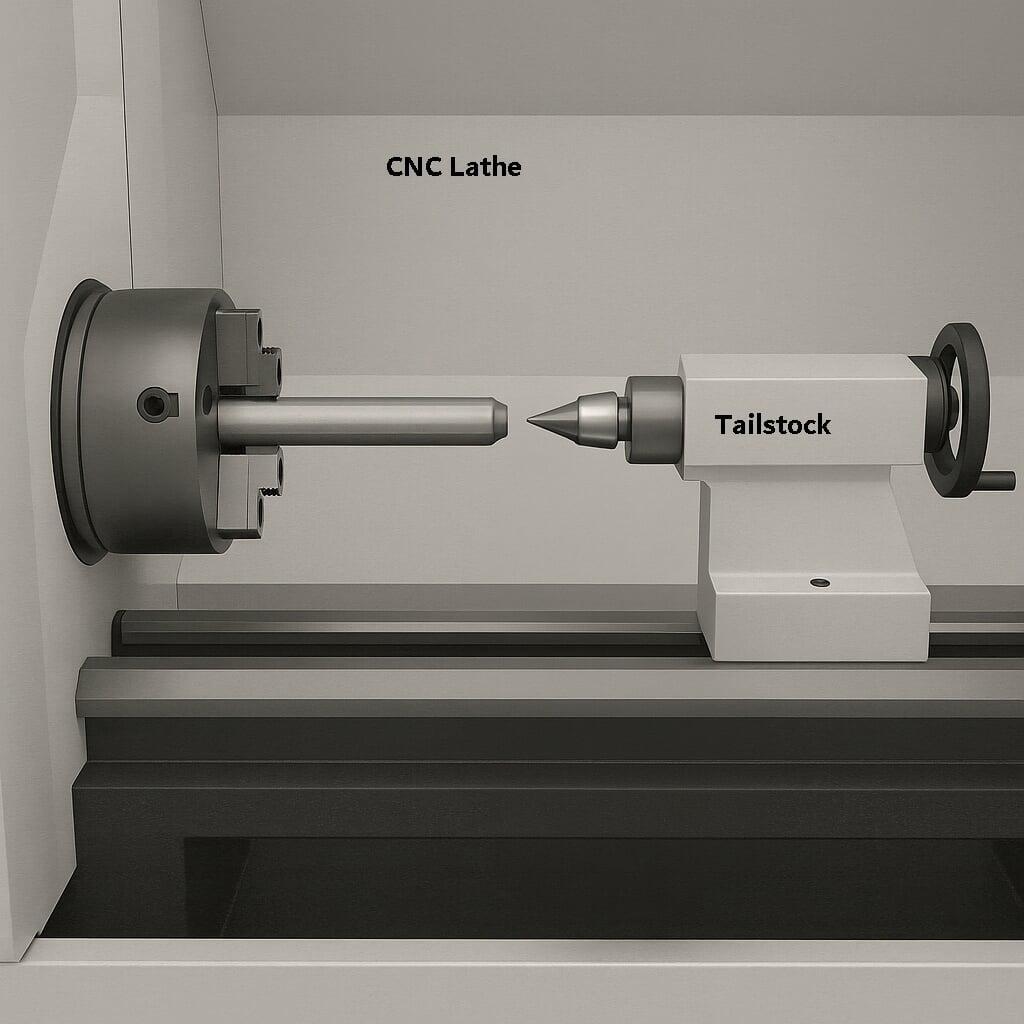

I am going to lean on my experience as a machine tool builder (CNCs, Robots, AGVs, Factory Automation).

With a new CNC Lathe development, the team decided that they were going to start from scratch. Everything worked well until we came to the tailstock. The way tailstock was designed and mounted, made it challenging to move and maintain position for between center jobs. A prior design had eliminated these issues and the team ended up adapting it with slight modification. Impact: delayed time to market by 12 weeks; lost first customer, whose requirements prompted the design.

Reviews showed that the design team was rebuilding similar configurations repeatedly, unable to find or trust prior design work. The engineering libraries were poorly organized, lacked documentation, and were not searchable. New team members, in particular, were unknowingly reinventing the wheel.

Further impact of this problem is that we were adding challenges to our manufacturing, warranty and service capabilities, by introducing new variables, which have been previously solved.| Impact | Symptom | Cost Implications | Benefits from Design Reuse |

| Time | Long quoting and engineering cycles | Lost deals, delayed revenue | Faster time to quote improves win rate, especially in capital sales |

| Quality | Rework due to new design variants | Warranty claims, customer dissatisfaction | Reduces rework, support costs |

| Inventory | SKU proliferation | Inventory bloat, higher carrying costs | Lower BOM costs, simplified sourcing |

| Talent | Repetitive work, difficult onboarding | Time to competency | Frees up capacity for NPD |

Critical Intervention: Embedding Reuse Principles into Design Practice

We started the discussion on design reuse. The design team and its leader understood the context of the problem through joint reviews and discussion. Actions taken:

Modularize all new designs

Tag them with consistent feature and naming conventions

Document configurations so variants could be easily understood

To ensure consistency and enable scale, we aligned tagging conventions with part feature, function, and interface fit. This made it easier to navigate the design library when seeking a component with similar constraints.

My observation: Engineers value creativity, rigor in design and dislike documentation and this change initially met with some resistance. Leadership positioned designs as long-lived assets, and their reuse directly showcased how impactful the engineers' work is in driving both throughput, quality and customer experience. We defined ‘reuse’ as sub-assembly reused with less than 10% design change. This let design leaders track module lineage across projects and identify which designs were repeatedly customized. Within six months, over 20% of common design tasks were being fulfilled using existing asset configurations. Key metrics tracked:

% increase in part library reuse

% of SKU reduction for inventory management

Digital Enablers for Reuse

Design reuse requires more than policy. It requires digital tools and CAD & ERP data hygiene. What it looked like for us:

Engineering Asset Libraries with searchable metadata, images, and part lineage

Simple product digital twins, models that simulate product configurations, helped us pre-check fitment, compatibility and interface of reused modules.

These digital enablers also provided early visibility into feasibility, and surfaced interference or manufacturability challenges that had already been resolved elsewhere in the system.

Now, tagging Assistants that auto-categorize designs based on shape, performance, or project history are available, but we did not get to use them.

What does Governance look like?

It requires and collaboration across departments:

Role Clarity: Who curates the design library? Who approves new modules?

Documentation Standards: What constitutes a “reuse-ready” design?

Reuse Metrics: How often is a design reused? By which teams? In what context?

Design Reviews: Periodic audits to identify reuse candidates and archive legacy variants

Incentives also matter. Tracking reuse can help showcase engineering effectiveness and free up cycles for new product innovation. In our case, reuse champions emerged organically.

Call to Action: Reuse as a Competitive Advantage

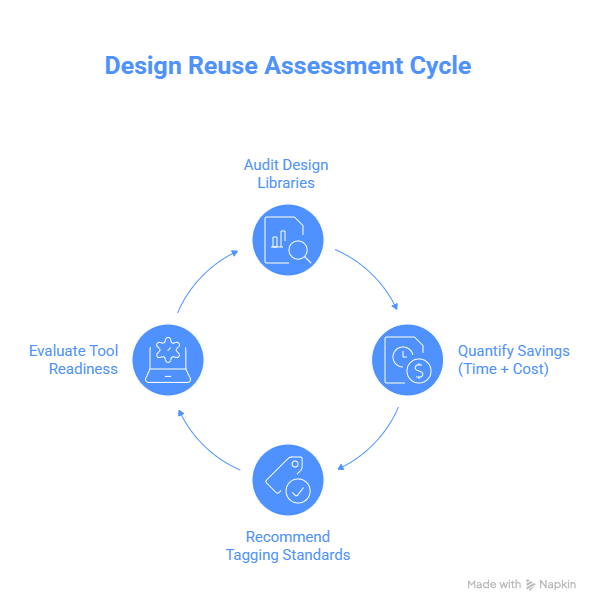

Steps to Assess Design Reuse:

Audit existing design libraries and identify duplicate work

Quantify time and cost savings potential

Recommend tagging standards

Evaluate readiness for CAD intelligence, CPQ and digital twin tool