Series: Designing Intelligence – The Strategic Use of Digital Twins in OEM Manufacturing

Introduction to the Series

In this three-part series, we explore how digital twins can help OEM manufacturers move from reactive decision-making to intelligent, data-driven operations. From early-stage design to procurement strategy and workforce enablement, digital twins—when implemented beyond surface-level 3D models—can serve as an integrated, cross-functional foundation for growth and resilience. The discussion is focused towards OEM in industrial engineered goods segments.

This three-part series explores how digital twins can serve as a force multiplier across:

Part 2: Operational Digital Twins for shopfloor and supply chain management

Part 3: Connected worker enablement and training scalability

Part 2: Operational Intelligence: How Digital Twins Strengthen Shopfloor and Supply Chain Performance

For many OEM manufacturers, operations are a daily balancing act involving long lead times, custom builds, equipment constraints, and workforce variability. Decision-making tends to be reactive—driven by siloed systems, tribal knowledge, and, more often than not, spreadsheets. It is remarkable how spreadsheets continue to dominate production execution, even in organizations with ERP and MES implementations. In my prior role as an OEM manufacturer, one ERP vendor suggested that we treat every client order as a special project, given the shopfloor routing changes required, instead of trying to establish standardized routing. Obviously, we did not select that vendor, but we did use that feedback to structure multi-stage BOMs with the ability to accommodate customization.

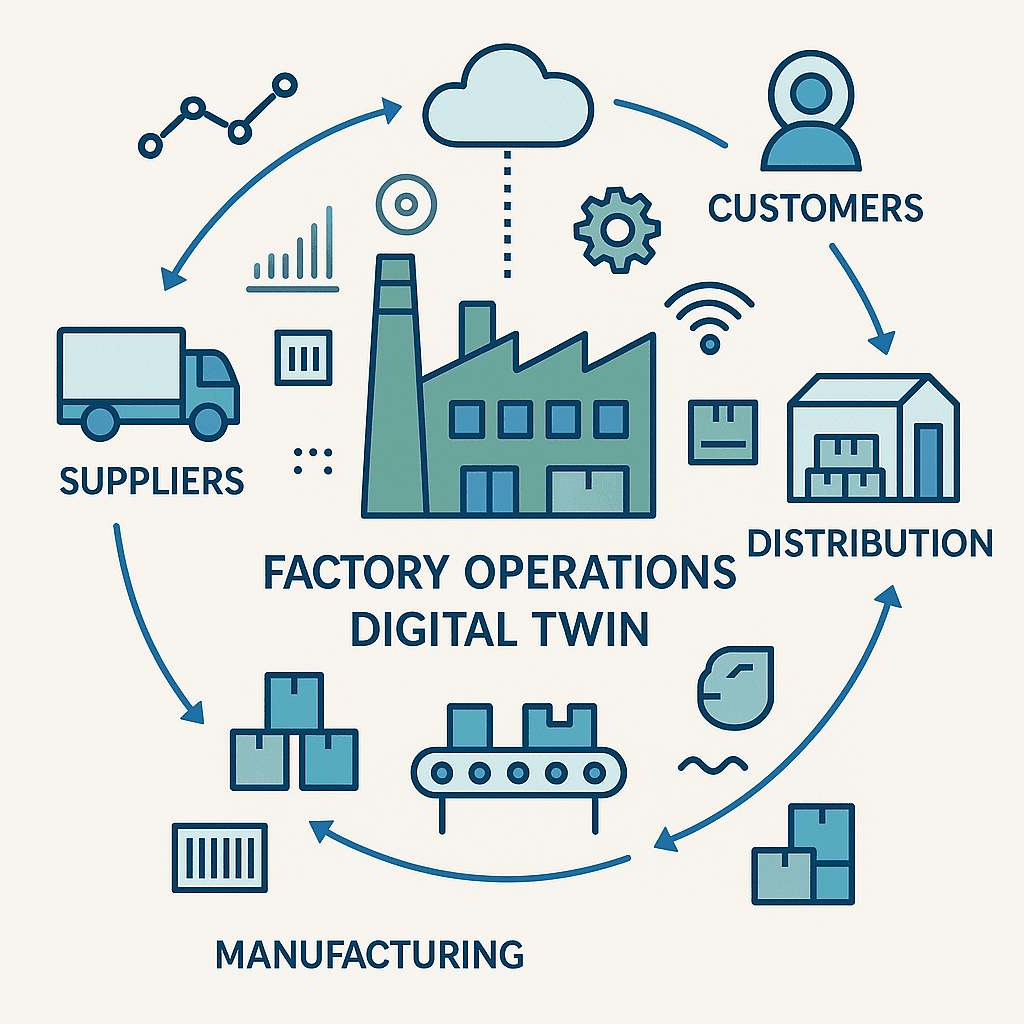

While digital twins are often viewed as 3D simulation tools, their true strength emerges on the factory floor. An operational digital twin redefines how OEMs manage manufacturing: providing a holistic, real-time view of operations, and empowering teams to anticipate disruptions, adapt plans, and act decisively. Unlike spreadsheets, which provide static snapshots, a digital twin continuously evolves with real-time input, offering foresight.

Execution Gaps in OEM Operations

Despite digital systems, many OEMs still face persistent execution challenges:

No unified operational view: data from supply chain, production, quality, and workforce exists in silos.

Custom client orders disrupt standard routing. Design changes rarely cascade cleanly into production.

Supply chain disruptions are spotted too late to react effectively.

Static schedules can't flex for absenteeism, machine downtime, or urgent orders.

MES data is transactional, not contextualized for predictive or scenario-based decisions.

What Is an Operational Digital Twin?

An operational digital twin is a live, integrated model of your factory environment. It mirrors conditions across machines, material flow, and workforce performance. It integrates:

MES, ERP, PLM, and supplier systems

IoT sensors, operator inputs, equipment diagnostics

BOMs, routing plans, design changes

Rather than building from scratch, OEMs should start by identifying which elements of this twin already exist and how to connect them.

Key Capabilities for OEMs

1. Shopfloor Visibility for Faster, Smarter Action

An operational twin bridges the gap between plans and execution:

Monitor machine loads, queues, and WIP.

Detect bottlenecks, idle equipment, and quality issues.

Forecast delays before they impact downstream tasks.

Supervisors gain live dashboards to reallocate resources dynamically, while still meeting production KPIs. Most likely, OEMs' MES + ERP systems, enhanced with API integrations, low-code workflow apps, and role-based dashboards, can deliver this visibility.

2. Discovering the Digital Twin Hidden in Plain Sight

Most OEMs already have partial elements of a digital twin in their ERP. With clear outcomes and a process map, these can be connected and visualized to understand the flow:

Inventory: Visualize material movements and cycle times with BI tools.

Supplier Deliveries: Model inbound flows to gauge cost and availability amid tariff changes.

Workforce: HR can map attendance and skills to dynamically adjust duty rosters.

Maintenance: Facilities teams can automate alerts through schedules, dashboards, or SMS in lieu of live IoT data.

3. Create an Ops Disruption Response Playbook

Disruptions are unavoidable. Digital twins allow teams to run "what-if" scenarios:

Model inventory, labor, and machine capacity impacts.

Shift orders across lines or reschedule by priority.

Simulate the impact of design or supplier changes across sourcing, manufacturing, quality, and even finance.

Identify alternates and cost effects proactively.

Engineered-to-order OEMs benefit especially from these dynamic capabilities, where change is the norm.

4. Change Management and Execution Readiness

In 2021, when a critical control component's lead time jumped from 30 to 450 days, we had to reconfigure our build process and execute quickly: redesign, set up a new source, rework test jigs, update documentation, and batch orders for cost reduction and to minimize customer impact. That is the simplified version. We used existing systems to model an operational twin (not fully integrated) and prepare our response plan. A digital twin can:

Highlight affected builds and documentation needs

Surface process steps, training, or skills gaps for execution

Align procurement, production, and quality teams automatically

Getting Started: Building Your Operational Twin

Every OEM knows it takes time to build manufacturing competencies. Take a long-term view of the capabilities you need and start building toward that vision. You don't need to digitize everything at once. Take inventory of what your teams already have. Start small:

Map recurring bottlenecks and areas of delay

Integrate available data from MES, IoT, or supplier platforms

Use simulations to test decision impacts before committing to changes

Engage planners, operators, and quality leads to validate workflows

Leverage your tool vendors: ask for use cases, demos, and training. Involve suppliers too—understand how they plan to provide you with better visibility, lead time forecasts, and capacity insights. (We often asked our top suppliers to share their product roadmaps, factory capabilities, and new industries they were exploring.)

Over time, the roadmap begins to take shape as a digital maturity model, with each capability supporting your workforce, decision-making, and business strategy.

Conclusion: The New Operational Edge

An operational digital twin is not about controlling everything—it is about knowing what to watch, understanding the impact, and acting early. It bridges planning with real-world execution, helping OEMs respond faster to disruption, deliver on time, and build trust across teams and with customers.

In Part 3 of this series, we’ll explore how digital twins empower OEMs with the connected worker strategy—streamlining training, support, and performance in increasingly complex production environments.