Evolving the Manufacturing Workforce

This past week, I participated in RIT's National Council for College of Engineering Technology. The discussions with industry leaders and faculty highlighted a genuine urgency: we must prepare students—and the workforce they will soon join—for the demands of evolving industries. That urgency is equally pressing for today’s manufacturers.

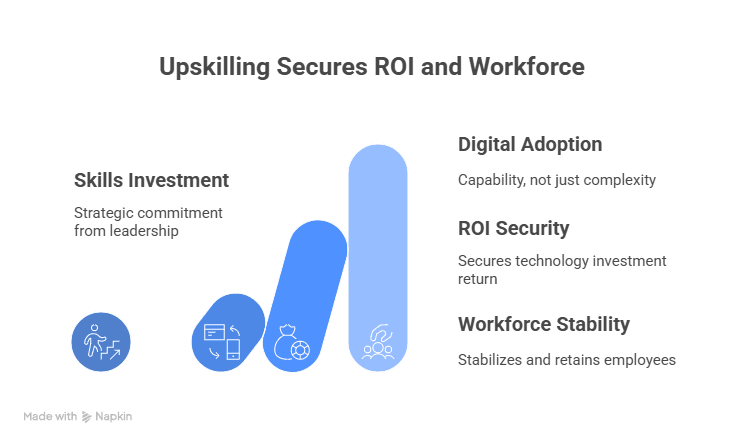

Technology adoption is accelerating in manufacturing, but workforce skills often lag. New automation, analytics, and digital platforms cannot deliver their promised value if people are not equipped to use them. Operators default to old habits, engineers underutilize systems, and ROI takes longer than expected.

Skills investment must run in parallel with technology investment. Without it, digital adoption risks becoming another layer of complexity rather than a source of capability. Skill investment is strategic; it takes time and it takes commitment from the C-suite.

This blog outlines a three-year upskilling roadmap designed for OEMs, ODMs, and capital equipment builders—manufacturers of CNC machines, packaging automation, and factory systems—where workforce readiness is the real bottleneck to realizing value.

Year 1: Build Baseline- Job Roles and Digital Awareness

Goal: Ensure the workforce is familiar with the digital tools already in place.

Updated job descriptions: Redefine roles and skills to reflect future competencies. Industrial associations can play an important role in helping members benchmark and standardize.

Clear role definitions are critical before training begins so employees understand expectations and growth paths.

Vendor-led onboarding: Require OEM and automation vendors to deliver role-specific training for operators, technicians, supervisors, and engineers.

In-house refresher modules: Develop short, practical content for ERP, MES, CAD, or CAM systems.

Microlearning: Introduce 15–20 minute shift-based sessions rather than full-day training.

Metrics: % of workforce completing baseline training, time to competency, reduction in basic operator errors, increase in ERP/MES usage rates

Year 2: Expand Applied Skills and Cross-Training

Goal: Move from awareness to confident application.

Role-based in-house certification: Build structured skill paths such as quality diagnostics, maintenance troubleshooting, or scheduling optimization.

Digital twin training: Use simulations to train operators on scenarios such as CNC machine jams or packaging line bottlenecks without interrupting production.

Cross-training: Enable line leads to interpret downtime dashboards and planners to handle dynamic scheduling.

Metrics: Reduction in downtime tied to operator error, shorter onboarding cycles for new employees, measurable OEE and throughput improvement.

Year 3: Embed Advanced Skills and Career Growth

Goal: Develop predictive and decision-support capabilities while improving retention.

Analytics literacy: Train supervisors and engineers to act on predictive maintenance data, throughput analytics, and scheduling recommendations.

Train-the-trainer programs: Build internal champions to sustain programs and reduce vendor dependence.

Career pathways: Link skill acquisition to advancement opportunities, pay scales, and progression into supervisory roles.

Metrics: Increase in ERP/ MES usage rates; reduced root cause analysis cycle time; higher retention of skilled workers.

Integrating Skills with Technology Investments

Every equipment or software investment should include a skills roadmap.

Negotiate structured training programs into vendor contracts.

Pair new systems with defined workforce learning modules.

Measure skills adoption alongside OEE, downtime, and throughput.

Upskilling is not an add-on. It is a direct enabler of ROI.

Retention Through Growth

Workers are more likely to stay when they see growth opportunities. Skills development sends a clear message: we are investing in your future, not just in machines. At MTAB Engineers, quarterly vendor-led training sessions were open to everyone, including shopfloor team members. This approach ensured knowledge-sharing across all levels and gave vendors direct insight into how components were used in practice. The results were tangible: greater efficiency, faster problem-solving, and stronger workforce retention.

Call to Action

If you are planning your next wave of automation, physical or digital, create a three-year workforce roadmap alongside it.

Year 1: Build baseline awareness.

Year 2: Apply and cross-train skills.

Year 3: Advance analytics literacy and career growth.

Technology will continue to evolve. Workforce skills must evolve with it. Intentional upskilling is a strategic necessity and the surest way to secure ROI and workforce stability.