Investing in Smart Manufacturing with Discipline

Most manufacturers have no shortage of technology options. They are short of time, attention, and capacity to absorb change. The real question is not “What should we buy next” but:

How do we sequence smart manufacturing investments so that we reduce chaos, avoid change fatigue, and move our operational and financial metrics in the right direction?

For CEOs, COOs, and owners, the way you sequence smart manufacturing investments will shape three decisions:

Which projects to fund now versus postpone

Where to say “not yet” to attractive technologies that are ahead of your readiness

How to allocate scarce leadership attention and capital over the next 12 to 18 months

Why maturity matters more than technology lists

Most manufacturers start with a list of technologies. That is the wrong starting point.

Before deciding what to implement, you need to know:

How stable are your core processes

How fragmented or connected is your data

How ready is your workforce to work with new tools and new ways of working

A structured maturity assessment such as SIRI does what “gut feel” cannot:

Creates a common language across leadership, operations, engineering, and IT

Exposes where digital foundations are weak, so higher value tools can be sequenced safely

On its own, maturity is not enough. You also need to understand it lands on your financials. That is the role of the Manufacturing Technology Balance Sheet.

MTBS links maturity gaps to:

Capacity and throughput

Quality and rework

Working capital (inventory, WIP days, spares)

Cost of delayed time to market and lost bids

Talent risk and training burden

Sequencing is critical to avoid bottlenecks and change fatigue

Poor sequencing shows up in very familiar ways:

The same process engineers and supervisors are pulled into three initiatives at once

New systems land on top of unstable processes, so people work around them

Everyone is “in workshops,” but OEE, lead times, and on time delivery remain unchanged

Operators see new tools as overhead.

Smart manufacturing initiatives create load along three dimensions:

Process load – changes in work instructions, routings, approvals, and responsibilities

Data load – new fields, new codes, new data entry expectations, and new system behaviors

People load – training, pilots, debugging, meetings, and mental overhead

If you stack high load projects on the same people and the same processes at the same time, you create real risk.

Sequencing is risk management. When you see two or more high load projects landing on the same roles or processes in the same quarter, it is a signal to reorder or resize the portfolio before resistance shows up as a performance problem.

Linking sequencing to the Manufacturing Technology Balance Sheet

The MTBS lens keeps you honest. Every initiative should be traceable to one or more of these questions:

Where are we losing capacity on critical assets

Where are we carrying unnecessary inventory or WIP

Where are we seeing rework, warranty, or scrap that erodes margin

Where are we exposed to workforce risk (retirements, skill gaps, training load)

A simple way to link sequencing to MTBS:

Rank value at stake.

For each area (capacity, quality, working capital, workforce), ask your finance lead for an order of magnitude estimate.Identify enabling dependencies.

Ask your team: “What must be true before this initiative can sustain?” For example, a scheduling optimizer depends on trustworthy routings and cycle time data.Place initiatives into three buckets.

Foundation: fixes that reduce chaos and unlock future options (for example, basic connectivity, event logging, BOM and routing clean up)

Multiplier: initiatives that amplify existing strengths (for example, expanding successful OEE pilots, digital work instructions in a stable line)

Optional: ideas that are attractive, but not yet supported by process or data maturity

Examples of phased implementation

Example 1: CNC Machine Builder OEM

Problem: Complex engineered to order machines, long lead times, frequent engineering changes, and heavy dependence on a few experts.

Phased sequence: Simplify design CAD structure into modules and emphasize reuse; Use simulation twin reference model to de-risk automation module and shorten commissioning; Connect field performance and service data for XaaS that impact you and your customer.

Outcome: At MTAB Engineers, our cost to serve was reduced by 10%.

Example 2: High mix component manufacturer

Problem: Many SKUs, frequent changeovers, unstable schedules, and constant firefighting by planners and supervisors.

Phased sequence: Instrument one bottleneck area and standardize changeover routines; Implement OEE and schedule reviews for that area and test batch sizes with a performance twin; Extend successful patterns to adjacent lines and link into planning.

Outcome: Typically. production capacity expanded by 15+%, without additional capital or manpower spend.

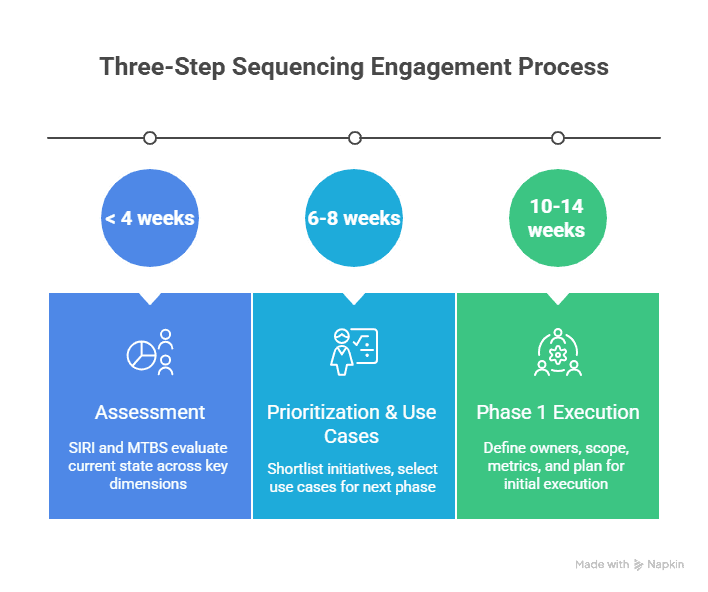

How I use SIRI and MTBS to structure a sequencing engagement

For clients, I combine SIRI and the Manufacturing Technology Balance Sheet into a three step service that answers three practical questions.

Where are we now

SIRI maturity assessment for you in relation to your industry

MTBS view of capacity, quality, inventory, and workforce risk

What should we do first

Shortlist of initiatives and sequencing logic based on dependencies and value at stake

Selection of one or two use cases for the next 3 to 9 months

How do we execute without chaos

Clear business and technical owners

Defined scope, success metrics, and a 90 to 120 day Phase 1 plan with explicit entry and exit criteria for Phase 2

This structure turns smart manufacturing into a disciplined capital allocation and capability building exercise.

Start with a SIRI led readiness and sequencing review

If you are considering new investments to expand manufacturing capabilities, the first step is a structured view of your maturity and your value at stake

I offer a SIRI based Smart Manufacturing Readiness and Sequencing Assessment that:

Benchmarks your current state across key Industry 4.0 dimensions in your industry

Links maturity gaps to MTBS metrics such as capacity, quality, and working capital

Prioritizes and sequences your next 12 to 18 months of technology investments

Defines one or two “no chaos” use cases for the next 3 to 6 months with clear success criteria

If you would like to explore a readiness and sequencing review for your operation, you can contact me through MTAB USAor via LinkedIn.